Innovative Gas Cleaning Solutions and Sustainability

Pioneering Environmental Change with Advanced Scrubbing Technology.

Get in touch with us

Technical developments are occurring at a rapid pace due to the increasing demand for new materials and more sustainable production processes on the way to a cleaner world. The challenge of meeting the demand for new technologies is increasing and requires us to think and act more and more creatively.

No matter how much work is being done on processes that no longer burden the environment and are climate-neutral, we are still dealing with existing installations and production techniques. It is impossible to reasonably expect that a turnaround can be achieved within a few years. However, it is possible to adapt existing processes in such a way that the burden on people and the environment is kept to a minimum.

Ravebo has been active for decades in developing and building custom-made industrial scrubbers for gas cleaning. The area of application is particularly versatile: from steel to foodstuffs, from chemicals to building materials, from reducing odor nuisance to removing particulate matter, and for flue gas cleaning.

In recent years, due to the obligation towards cleaner production processes, increased recycling of materials, and reuse of products, the emphasis on the development of scrubbers has evolved significantly.

Previously, a scrubber was considered an end-of-pipe system that required a certain reduction of contaminants. Nowadays, the call for sustainability and the tightened emission limit values not only have a significant influence on the configuration, but the scrubbers must be realized as a completely turn-key project. This means, for example, that control systems must be included, emissions must be monitored in situ with specific, high-end gas analyzers and the recuperation of the washing liquids must be realized.

At the same time, new applications for scrubbers have emerged, such as cleaning syngas from pyrolysis processes, odor reduction at biomass fermentation, gas cleaning when manufacturing biofuels and gas purification in metal recycling.

We use On Topic to highlight the latest news about groundbreaking processes and sophisticated applications. We trust that we can make a sustainable contribution to a cleaner environment, and we strive for a more livable world.

Advanced Syngas Wet Scrubbing Solutions

Syngas at its Cleanest, Efficiency at its Finest!

Syngas, produced through gasification, often contains impurities like fine dust, alkali and nitrogen compounds, tar, and various hydrocarbons, which can cause operational issues such as corrosion and clogging. Ravebo's wet gas scrubbing technology aims to reduce these impurities, making syngas suitable for use in combustion engines or methanization systems. The technology includes open spray systems with ultrafine droplets for efficient particle capture, and counter current scrubbers with multiple washing sections for thorough cleaning. The scrubbers are designed to minimize pressure loss and are easy to maintain, emphasizing environmental compliance and operational efficiency.

Read more...

Advanced Mineral Processing & Emission Reduction

Optimizing Mineral Processing for Environmental Excellence

Minerals, used in numerous industries, generate fine dust during production and transportation, posing potential hazards. The page details the various forms and uses of minerals, highlighting their critical role in industries like building, food, pharmaceuticals, and renewable energy. It also discusses the environmental impacts of mineral processing, including air quality concerns from airborne particulates. Ravebo offers specialized solutions like wet gas scrubbers and dust scrubbers, tailored to process requirements, to mitigate these environmental impacts. Additionally, the page stresses the significance of mineral recycling in conserving resources and reducing environmental damage from mining and processing.

Read more...

Bio-Based Emission Control Technologies

Revolutionizing Environmental Sustainability with Bio-Based Emission Scrubbing

This webpage dedicated to bio-based technology and odor control in biorefineries and biofuel plants highlights the evolving landscape of renewable energy and its challenges. It discusses the increased use of biofuels to reduce CO2 emissions and reliance on fossil fuels. Biomass, defined by European Directive 2009/28/EC, includes biodegradable agricultural, forestry, and industrial residues. In bio-based economies, the use of biological residuals faces challenges like odor control and gas emissions. Ravebo specializes in odor control units (OCUs) and open spray scrubbers for efficient particle capture. These systems comply with the Industrial Emission Directive (IED, Directive 2010/75/EU) for controlling odor emissions, utilizing advanced gas analyzers for precision. The webpage underscores the complexity and importance of managing emissions in biofuel production to achieve sustainability goals.

Read more...

Comprehensive Metal Processing & Emission Control Solutions

Innovative Technologies for the Metal Industry: Ensuring Sustainability and Efficiency

Metals, indispensable in everyday life, are extensively used in building materials, transportation, electronics, and household items. The production of renewable energy technologies like solar panels, electric cars, and wind turbines has significantly increased the demand for various metals, including rare ones like cobalt, lithium, and neodymium. Metals are categorized into ferrous (iron and its alloys like steel), non-ferrous (e.g., aluminum, gold, copper), and heavy metals (like lead, mercury, and cadmium). The extraction and refining of metals from ores are energy-intensive processes, often impacting the environment through energy consumption, water pollution, and emissions of SOx, NOx, and CO2. Metal recycling is highlighted for its environmental benefits, significantly reducing energy use, air and water pollution, and resource depletion. Ravebo also discusses its advanced wet gas scrubbers, designed for the metal industry to efficiently reduce emissions and comply with environmental directives.

Read more...

Advanced BTEX Control with Wet Gas Scrubbers

Effective BTEX Emission Reduction: Innovative Scrubber Technologies

BTEX compounds, derived from petroleum, are harmful to health and the environment, affecting the central nervous system and contributing to air pollution and ozone formation. Ravebo's wet gas scrubber technology, employing (bio)diesel with alcoholic additives as washing liquids, effectively removes BTEX from gas streams. Their open spray scrubbers, known for low energy consumption and maintenance, use ultrafine droplets for efficient particle capture. Additionally, the page details the use of Fourier Transform Infrared (FTIR) analyzers for accurate identification and quantification of gas components.

Read more...

Wastewater Treatment Odor Control Solutions

Advanced Wet Scrubber Technologies for Wastewater Odor Mitigation

The Ravebo website's page on wastewater treatment focuses on odor control in wastewater treatment facilities, highlighting the growing trend towards adopting diverse water treatment technologies. Wet scrubber systems are crucial in this process, controlling odors from primary and secondary treatment systems, as well as biosolids-processing facilities. Hydrogen sulfide (H2S), with its rotten-egg odor, is a significant concern due to its health hazards. Wet scrubbers effectively convert hazardous fumes into a liquid solution, using chemical additives and water mists. This process effectively removes toxic and flammable gases like H2S. Consequently, wastewater treatment plants are increasingly investing in advanced odor control systems, including scrubbers and gas strippers, to ensure air and water purity before discharging treated water into natural bodies.

Read more...Game-changing benefits

Discover the game-changing benefits of scrubbers and propel your business forward with our free whitepaper download.

Sustainable Practices in the Pharmaceutical Industry for Emission Reduction

Navigating Emission Control in the Growing Pharmaceutical Sector

Sustainable Pharma discusses the pharmaceutical industry's significant contribution to global carbon emissions and the importance of emission control. The industry, growing rapidly due to increased emphasis on personal well-being and aging populations, contributes about 5% to the global carbon footprint, emitting around 52 megatons of CO2 equivalents globally. Pharmaceutical production often involves organic solutions that emit harmful pollutants like PAHs, VOCs, and particulate matter, necessitating stringent environmental regulations and effective emission control measures. Wet gas scrubbers are highlighted as an efficient solution for removing diverse pollutants from gas streams. Additionally, Fourier Transform Infrared (FTIR) analyzers are used for precise identification and quantification of various gas components, enhancing the effectiveness of emission control strategies in the pharmaceutical sector.

Read more...

Cyanides: Diverse Roles and Risks

From Industry to Nature, a Double-Edged Sword

Cyanides, encompassing substances like hydrogen cyanide (HCN), potassium cyanide (KCN), and calcium cyanide (Ca(CN)₂), play a pivotal role across various sectors despite their toxicity. Hydrogen cyanide, found naturally and used industrially, is crucial for producing essentials such as vitamins and certain medications. Its applications extend to the paper, nylon, plastic, and textile industries, and significantly, to mining for gold and silver extraction. The method involving cyanide in gold extraction, despite its efficiency and being deemed the safest by experts, faces criticism for environmental impacts and the high waste production associated with it. Additionally, cyanides are utilized in electroplating, chemical syntheses, and even in pest control historically. Safety measures in handling cyanide, given its potential fatal exposure, include stringent regulations, extraction systems, and proper waste treatment processes. The complexity of safely utilizing cyanide underscores its indispensable yet hazardous nature in modern applications.

Read more...

Understanding Black Carbon and Its Environmental Impact

Mitigate Industrial Soot Emissions

Black carbon contributes significantly to air pollution and climate change. It absorbs sunlight, leading to localized warming and altering atmospheric patterns. Its deposition on ice and snow reduces their reflectivity, accelerating melting. Additionally, it affects agricultural productivity and ecosystem dynamics. Mitigation efforts involve reducing emissions through cleaner technologies, such as the RAVEBO scrubber, which efficiently captures black carbon particles. Awareness and policy measures are crucial for addressing this pervasive pollutant and mitigating its far-reaching impacts on public health and the environment.

Read more...

Odor Nuisance and Management in the Food Industry

Exploring the Impact and Solutions for Odor Control

Odor nuisance in the food industry significantly affects air quality and community well-being, primarily due to emissions from processes like fish processing and baking. These odors, containing substances such as aldehydes and VOCs, not only deteriorate local air conditions but also lead to health complaints among nearby residents. Dispersion modeling is often employed to assess and manage these odors effectively. Additionally, the industry recognizes the profound influence of odor on the flavor perception of food, which integrates multiple sensory inputs including taste and smell. The article discusses various methods to measure and quantify odor nuisance, highlighting the use of European odor units and olfactometry to gauge the severity of odor in the environment. It also covers the technology behind gas scrubbers, a prevalent method for minimizing odor emissions by absorbing gases into liquids, crucial for meeting emission standards and improving air quality.

Read more...

Effective Emission Control with Tailor-Made Tank Scrubbers and Vapor Recovery Systems

Custom Solutions for Managing Harmful Gas Emissions in Liquid Transfer Operations

Tank scrubbers and vapor recovery systems are essential for controlling harmful gas emissions during the loading and unloading of liquids from ships, trucks, and trains. Venting prevents pressure buildup in storage tanks, which could lead to dangerous situations. There are two types of vapor return systems: passive systems that rely on liquid displacement, and active systems used in static applications that require multi-stage purification and pressure control.

Each storage tank often requires an individual cleaning process to prevent cross-contamination of gases. Wet gas scrubbers are widely used for vapor return systems, offering efficient liquid-gas separation. They are particularly effective for vent gas scrubbing in tank farms, thanks to their compact design and low maintenance needs.

Ravebo offers tailor-made scrubbers for various applications, from truck terminals to large maritime operations, meeting stringent global emission standards while providing customized solutions to reduce harmful gas emissions.

Read more...

Green Ammonia as a Hydrogen Carrier

A More Efficient and Sustainable Fuel Alternative

Green ammonia is poised to play a pivotal role in the transition from fossil fuels to sustainable energy sources. It offers numerous advantages as a hydrogen carrier and as an eco-friendly alternative to traditional fuels. The widespread use of green ammonia will require expanding production capacities, developing infrastructure, and enforcing strict regulations. Produced from renewable energy with zero carbon emissions, green ammonia enables the efficient transportation and storage of hydrogen, thanks to its higher energy density. Additionally, ammonia's use in various industries is expected to increase, necessitating improved transportation methods and enhanced safety measures. Environmental regulations are crucial, with technologies like gas scrubbers helping to reduce emissions. Green ammonia’s versatility, coupled with its significant potential to meet global energy needs, makes it a key player in the future of energy.

Read more...

Emission Reduction in Pyrolysis for Sustainable Biochar and Pyrolysis Oil

Advanced Purification Techniques for Biochar, Pyrolysis Oil, and Syngas

Pyrolysis processes produce biochar and pyrolysis oil, valuable products derived from biomass through thermal decomposition. Biochar enhances soil quality, sequesters carbon, and serves in filtration, while pyrolysis oil provides a renewable alternative to fossil fuels, reducing greenhouse gas emissions by up to 90%. Effective syngas purification with wet gas scrubbers ensures these gases can substitute natural gas, minimizing environmental impact. Advanced water purification systems using vacuum belt filters and centrifugal separators maintain process efficiency, reducing wear on equipment and conserving resources. Together, these technologies promote sustainable solutions in energy recovery and material processing.

Read more...

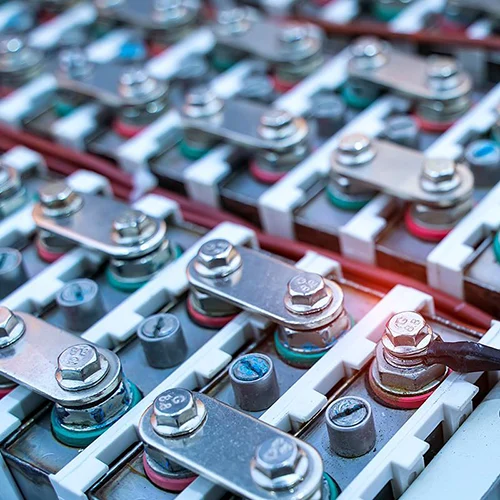

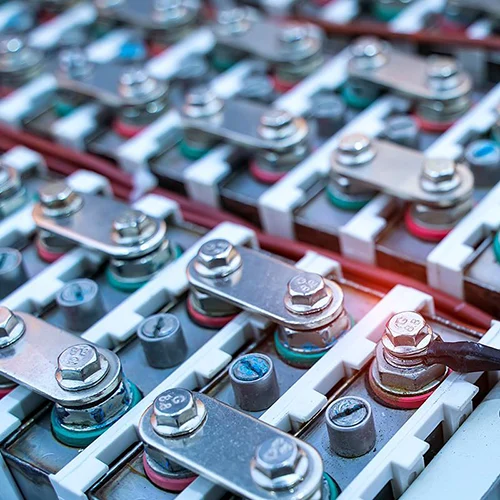

Advanced Emission Control and Gas Analysis for Battery Production

Ravebo's Role in Enhancing Safety and Sustainability

The rapid growth of battery production, driven by decreasing costs and clean energy demands, has transformed industries and highlighted new safety and environmental challenges. Ravebo addresses these challenges with innovative solutions, including the Gasmet GT6000 Mobilis, a high-performance multicomponent gas analyzer, and advanced wet gas scrubbers. The GT6000 Mobilis ensures precise real-time analysis of hot and humid gas streams, while Ravebo’s scrubbers effectively prevent harmful emissions, featuring near maintenance-free operation and compact, vertical designs. Adhering to international standards like EN-IEC 62619 and EN-IEC 62485, Ravebo's technologies support safe, efficient battery testing and production processes. These systems cater to rigorous testing scenarios, from temperature-controlled cycles to stress tests, ensuring both compliance and sustainability. With a focus on user-friendly, plug-and-play designs, Ravebo empowers scientists and industries to advance low-carbon, reliable energy solutions without compromising safety or environmental integrity.

Read more...

Sulfur Dioxide Emission Control

Wet Gas Scrubbers for Effective SO₂ Removal

Sulfur dioxide (SO₂) is a harmful gas released during the combustion of fossil fuels and the smelting of sulfur-containing ores. It poses significant environmental and health risks, including respiratory issues and ecosystem damage. Flue Gas Desulfurization (FGD) is a technology designed to remove SO₂ from exhaust gases in industrial processes. Wet gas scrubbers are a common FGD method, utilizing a liquid spray to absorb and neutralize SO₂ emissions. This process effectively reduces the release of sulfur oxides into the atmosphere, mitigating their adverse effects. Implementing FGD systems is crucial for industries to comply with environmental regulations and protect public health.

Read more...Get in touch with our scrubber specialist

Boost your industrial processes with our advanced wet gas scrubbers. Our specialist is ready to guide you towards efficiency, productivity, and environmental compliance. Connect with us now for expert advice, custom solutions, and quick responses. Let's find your perfect scrubber solution today.