Pyrolysis: Transforming Waste into Valuable Resources

Customised advise from one of our specialists.

Fill in the form below and we will contact you as soon as possible.

Let's Talk!

Pyrolysis

Pyrolysis: Transforming Waste into Valuable Resources

Pyrolysis is an innovative and increasingly essential technology used in industries aiming to convert waste into valuable resources. By thermally decomposing organic materials at high temperatures in the absence of oxygen, pyrolysis produces useful outputs such as syngas, bio-oil, and char. These products have diverse applications in renewable energy, chemical manufacturing, and sustainable material production. At Ravebo, we specialize in solutions that support pyrolysis processes, particularly in the crucial stage of syngas cleaning. With our advanced scrubber systems, we ensure that the gases produced during pyrolysis are efficiently purified, enabling their safe and effective use in downstream applications.

How it works

What is Pyrolysis?

Pyrolysis is a thermal decomposition process that breaks down organic materials into smaller molecular compounds through the application of heat. Unlike combustion or gasification, pyrolysis occurs in the absence of oxygen, preventing complete oxidation and producing three primary outputs:

- Syngas (Synthetic Gas): A mixture of carbon monoxide (CO), hydrogen (H₂), and other gases, often used as a renewable energy source or chemical feedstock.

- Bio-Oil: A liquid fuel or chemical precursor derived from the condensed vapors of the process.

- Char: A solid, carbon-rich residue with applications in agriculture (as biochar) or as a fuel source.

Partner with Us Today!

Opportunities

Challenges in Pyrolysis Gas Cleaning

While pyrolysis offers significant opportunities for resource recovery and energy production, the syngas it generates often contains impurities that must be removed before the gas can be used. Common contaminants in pyrolysis gas include:

- Particulates: Fine dust or soot.

- Tars: Heavy hydrocarbons that can condense and clog equipment.

- Acidic Gases: Such as hydrogen chloride (HCl) and sulfur compounds.

- Ammonia (NH₃): A by-product that requires careful handling.

Failure to clean these impurities can lead to operational inefficiencies, equipment damage, and non-compliance with environmental regulations.

GC-based BTEX analyzer

Our Role in Pyrolysis Processes

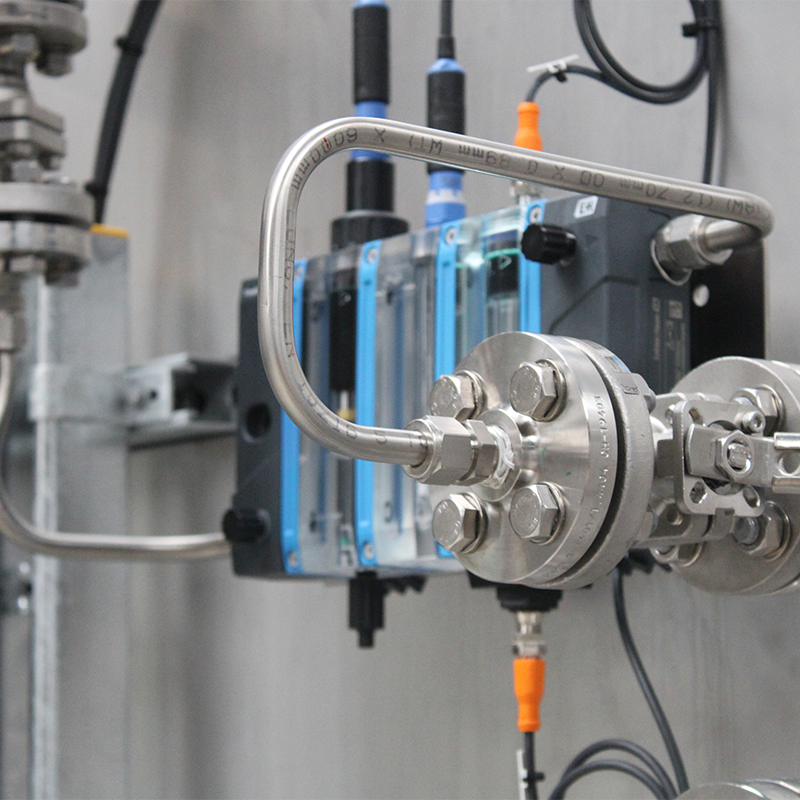

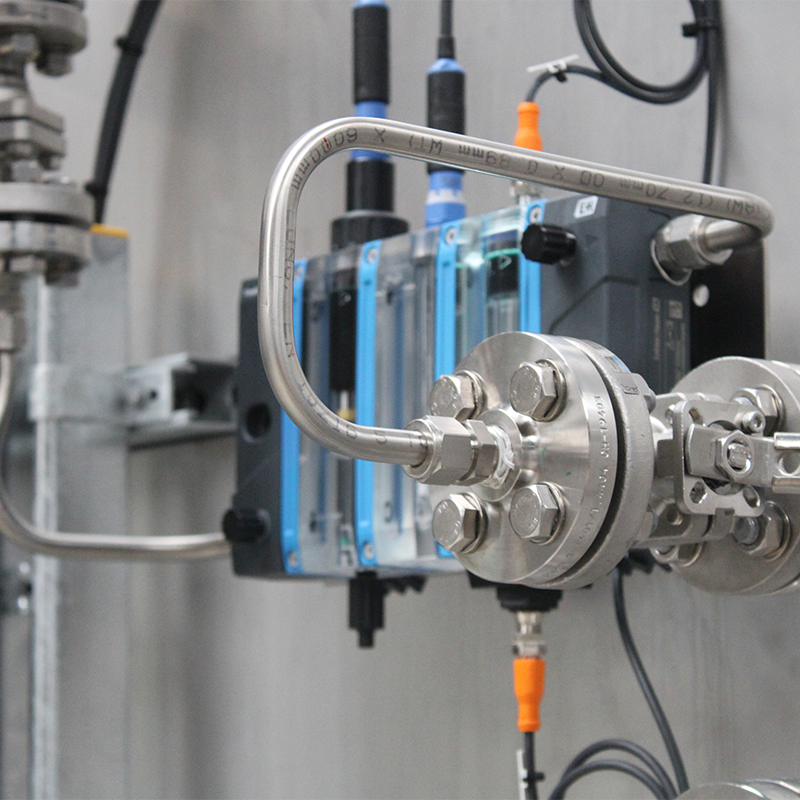

At Ravebo, we provide advanced syngas scrubbers designed to meet the unique challenges of pyrolysis gas cleaning. Positioned directly after the pyrolysis reactor, our scrubbers play a critical role in preparing the syngas for downstream applications.

Key Features of Our Syngas Scrubbers:

- Particulate Removal: Efficiently captures fine particles and dust, ensuring clean gas output.

- Tar and Condensable Removal: Our scrubbers prevent tar condensation, maintaining system efficiency and protecting.

- Acid Gas Neutralization: Advanced chemical scrubbing techniques neutralize acidic compounds like HCl and sulfur compounds.

- Ammonia and VOC Reduction: Designed to remove ammonia and other volatile organic compounds, ensuring compliance with environmental standards.

- Customizable Designs: Each scrubber is tailored to the specific composition of the pyrolysis gas and the requirements of the downstream application.

Various industries

Applications of Pyrolysis and Syngas Cleaning

- Renewable Energy Production Clean syngas can be used in gas turbines or internal combustion engines to generate electricity and heat.

- Chemical Feedstock Purified syngas serves as a valuable input for producing methanol, hydrogen, and other chemicals.

- Waste Management Pyrolysis is widely applied to convert plastic waste, biomass, and other organic materials into usable products, with syngas cleaning being a vital step in the process.

- Agricultural Applications Char produced during pyrolysis can be used as biochar to improve soil fertility, while clean syngas powers on-site operations.

Game-changing benefits

Discover the game-changing benefits of scrubbers and propel your business forward with our free whitepaper download.

Advantages

Why Ravebo is Your Partner for Pyrolysis Solutions

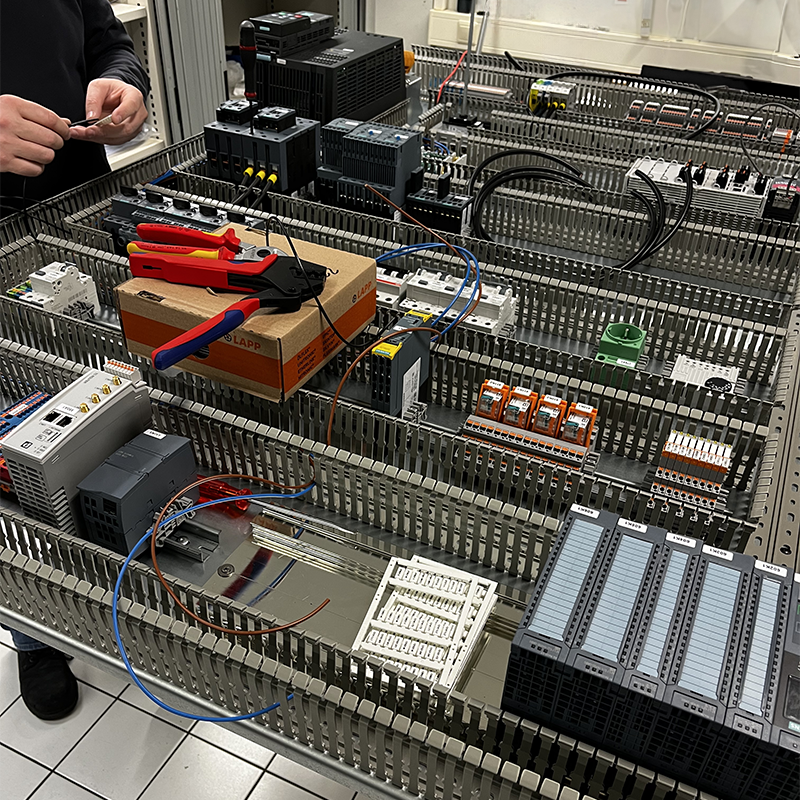

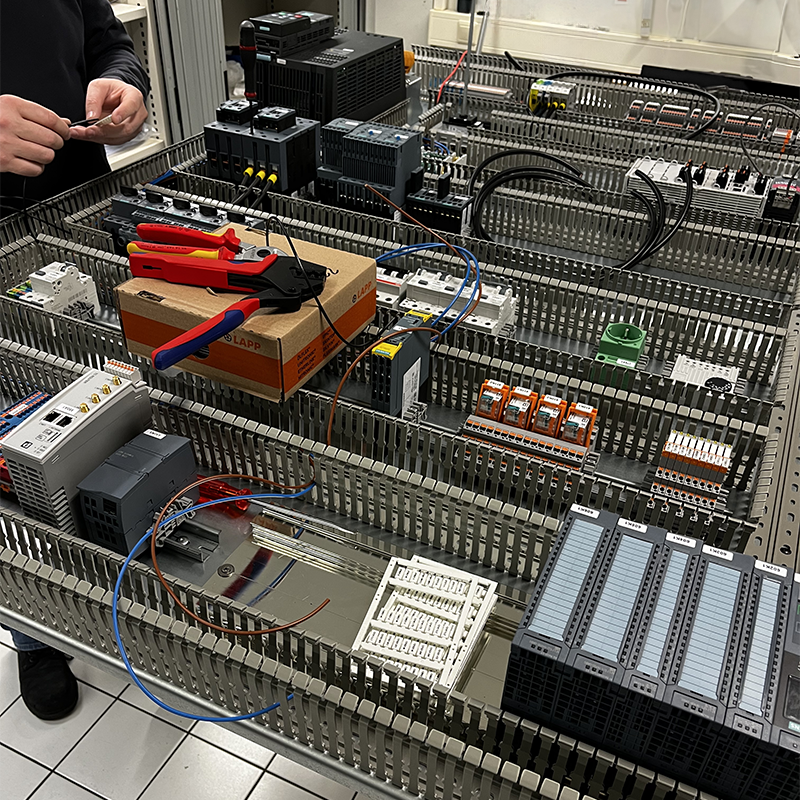

At Ravebo, we understand the complexities of pyrolysis processes and the critical role gas cleaning plays in their success. With decades of experience in designing and manufacturing custom gas scrubbers, we are uniquely positioned to support your pyrolysis operations.

Benefits of Partnering with Ravebo:

- Tailored Expertise: Our solutions are customized to meet the specific challenges of your pyrolysis setup.

- Integrated Approach: We work closely with you to ensure seamless integration of our scrubbers into your existing processes.

- Proven Technology: Our systems are built to handle the demanding conditions of pyrolysis gas cleaning, ensuring reliable performance.

- Regulatory Compliance: We help you meet environmental standards with efficient pollutant removal.

- Sustainability Focus: Our solutions support the broader goals of resource recovery and circular economy initiatives.

Get in touch

Pyrolysis and the Future of Sustainability

As industries worldwide seek to reduce waste and transition to cleaner energy sources, pyrolysis offers a powerful solution. By converting waste materials into valuable outputs like syngas, pyrolysis supports sustainability goals while driving innovation in energy and materials. At Ravebo, we are proud to play a role in advancing pyrolysis technology by providing reliable and efficient gas cleaning solutions. Whether you’re optimizing an existing process or developing a new pyrolysis application, our expertise ensures you have the support you need for success.

Partner with us for your Pyrolysis needs

Are you involved in pyrolysis processes and looking for a trusted partner to handle your syngas cleaning requirements? Ravebo offers state-of-the-art scrubber systems that deliver clean, reliable results, ensuring your operations are efficient, compliant, and sustainable. Contact us today to learn more about our solutions and how we can support your pyrolysis process from start to finish.

Get in touch with our scrubber specialist

Our gas scrubbers with analyzing systems make it possible to clean various gas flows. This leads to a cleaner living environment and more sustainable production processes. Curious about the possibilities? Our specialists are happy to provide you with appropriate advice.