Advanced BTEX Monitoring

for Effective Emission Reduction

Customised advise from one of our specialists.

Fill in the form below and we will contact you as soon as possible.

Let's Talk!

BTEX compounds

Measurement principles

Industries handling volatile organic compounds (VOCs) often face challenges in managing emissions of BTEX compounds—benzene, toluene, ethylbenzene, and xylene. These pollutants are hazardous to both human health and the environment, making their monitoring and control a critical priority. A key technology in this effort is the use of advanced gas chromatography (GC) analyzers integrated with wet gas scrubbers, enabling precise measurement and reduction of BTEX emissions. This article explores the measurement principle of GC-based BTEX analyzers and their role in enhancing the efficiency of wet gas scrubbers for emission control.

How it works

What Are BTEX Compounds?

BTEX compounds are a group of VOCs that are commonly emitted during industrial processes such as:

- Petrochemical Production

- Oil Refining

- Paint and Solvent Manufacturing

- Waste Management and Incineration

Due to their toxicity and contribution to air pollution, strict regulations govern the permissible levels of BTEX emissions. Effective monitoring and control solutions are essential to meet these standards.

Partner with Us Today!

The Measurement Principle

Gas Chromatography for BTEX Detection

The BTEX analyzer used in conjunction with wet gas scrubbers relies on gas chromatography (GC), a powerful analytical technique for separating and quantifying complex mixtures of gases. Here’s how it works:

- Sample Collection: A sample of the exhaust gas is extracted from the process stream. The analyzer’s sampling system ensures that even low concentrations of BTEX are captured accurately.

- Separation of Compounds: The gas sample is injected into a GC column, where different BTEX components are separated based on their chemical properties and interaction with the column's material.

- Detection: As the compounds exit the column, they are detected and quantified using a specialized detector, such as a flame ionization detector (FID). The detector provides high sensitivity and specificity for hydrocarbons like BTEX.

- Data Analysis: The analyzer processes the signals from the detector, providing real-time data on the concentration of each BTEX compound. This process allows for continuous and precise monitoring of BTEX levels, making it ideal for emission control applications.

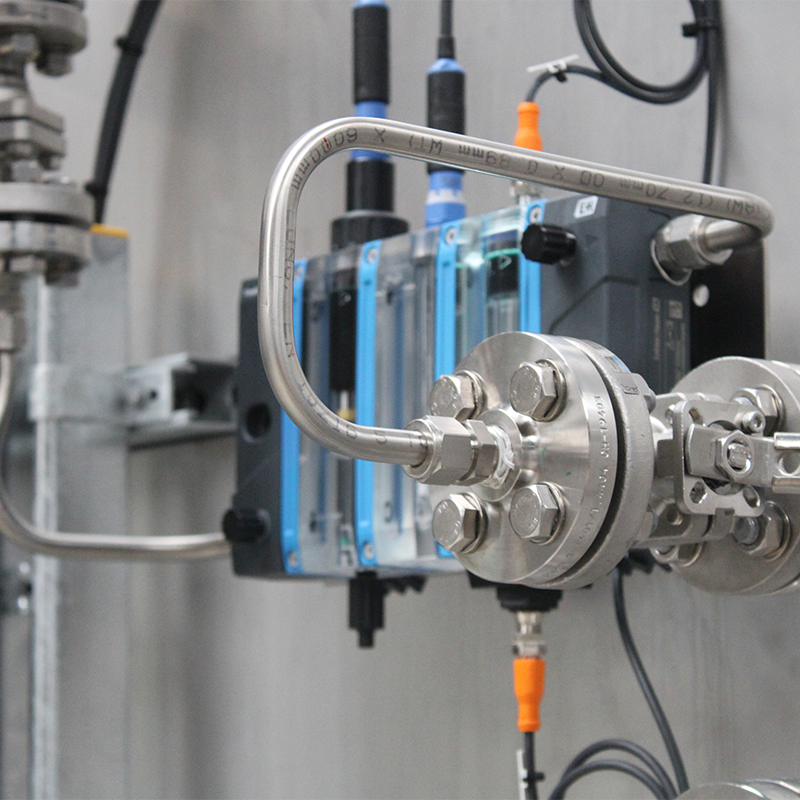

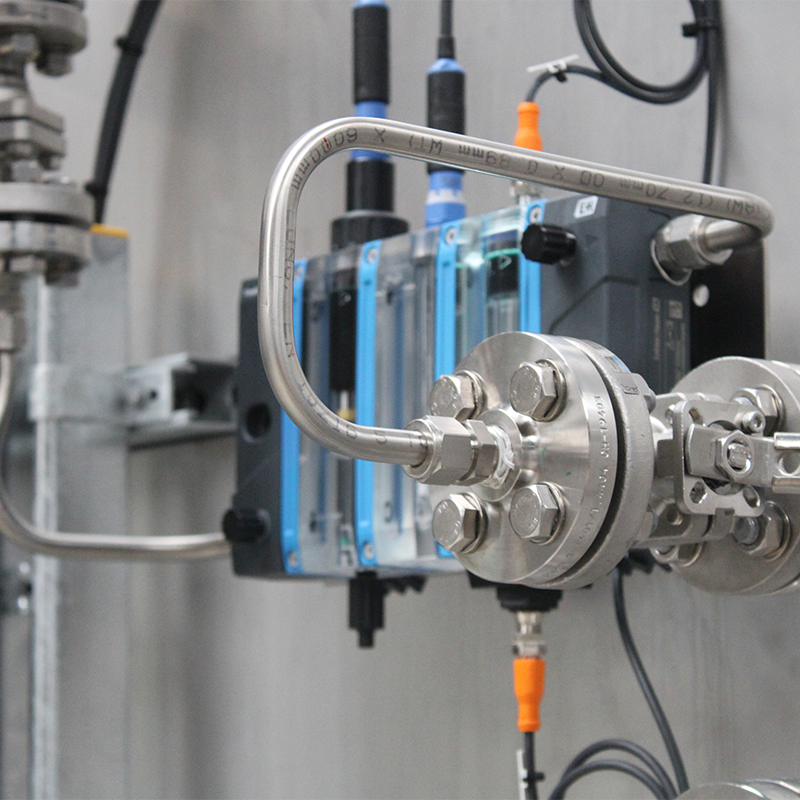

GC-based BTEX analyzer

Integration with Wet Gas Scrubbers

The GC-based BTEX analyzer is a critical component of wet gas scrubber systems designed for reducing VOC emissions. Here’s how it contributes:

- Real-Time Monitoring: The analyzer provides real-time data on BTEX concentrations in both incoming and treated exhaust gases, enabling operators to assess the scrubber's efficiency.

- Process Optimization: By monitoring BTEX levels continuously, operators can adjust the scrubber's parameters (e.g., liquid flow rate or chemical additives) to ensure optimal removal efficiency.

- Regulatory Compliance: Accurate measurement of BTEX emissions ensures compliance with strict environmental regulations, avoiding fines and reputational risks.

- Emission Reduction: The analyzer supports the efficient operation of wet gas scrubbers, enabling the capture and removal of harmful BTEX compounds before they are released into the atmosphere.

Applications of BTEX Monitoring in Wet Gas Scrubbing

- Petrochemical Industry Monitoring emissions from production processes and ensuring compliance with emission limits.

- Refineries Controlling BTEX levels in flue gases generated during refining operations.

- Paints and Coatings Manufacturing Managing solvent-based VOC emissions to maintain air quality standards.

Game-changing benefits

Discover the game-changing benefits of scrubbers and propel your business forward with our free whitepaper download.

Advantages

GC-Based BTEX Monitoring

Using gas chromatography for BTEX detection in wet gas scrubbers offers several benefits:

- High Sensitivity: Detects even trace levels of BTEX compounds.

- Accuracy and Specificity: Separates and quantifies each BTEX component individually, providing detailed insights.

- Real-Time Data: Enables continuous monitoring and quick adjustments to scrubber operations.

- Reliability in Harsh Environments: Designed to operate in challenging industrial conditions.

- Regulatory Compliance: Supports adherence to stringent emission standards, ensuring safe and legal operations.

Get in touch

Why Choose Ravebo for BTEX Monitoring Solutions?

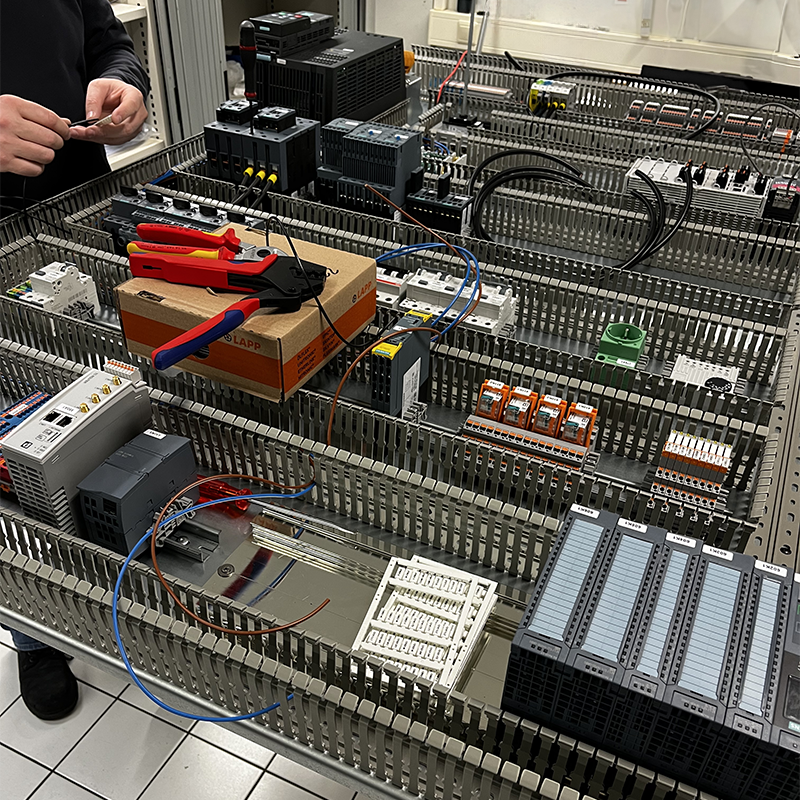

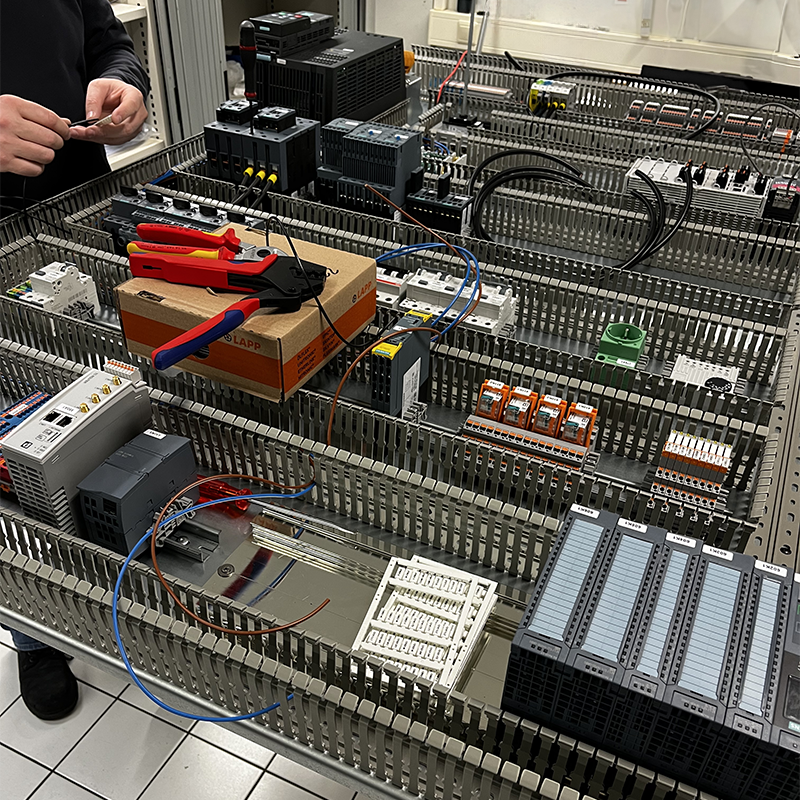

At Ravebo, we integrate state-of-the-art GC-based BTEX analyzers with our custom-designed wet gas scrubbers to provide comprehensive emission control systems. Our solutions are tailored to meet the specific needs of your operations, ensuring maximum efficiency and reliability.

Key benefits of our systems

- Tailored Integration: Each analyzer is seamlessly integrated with our wet gas scrubbers for optimal performance.

- Comprehensive Support: From installation to maintenance, we provide end-to-end service.

- Proven Expertise: With decades of experience in emission control, we are a trusted partner for industries worldwide.

Partner with us for advanced BTEX control

Reducing BTEX emissions is essential for industries committed to sustainability and regulatory compliance. At Ravebo, we combine cutting-edge BTEX monitoring technology with our expertise in wet gas scrubbers to deliver efficient, reliable, and sustainable solutions. Contact us today to learn more about our BTEX monitoring systems and how we can help you achieve your emission control goals.

Get in touch with our scrubber specialist

Our gas scrubbers with analyzing systems make it possible to clean various gas flows. This leads to a cleaner living environment and more sustainable production processes. Curious about the possibilities? Our specialists are happy to provide you with appropriate advice.