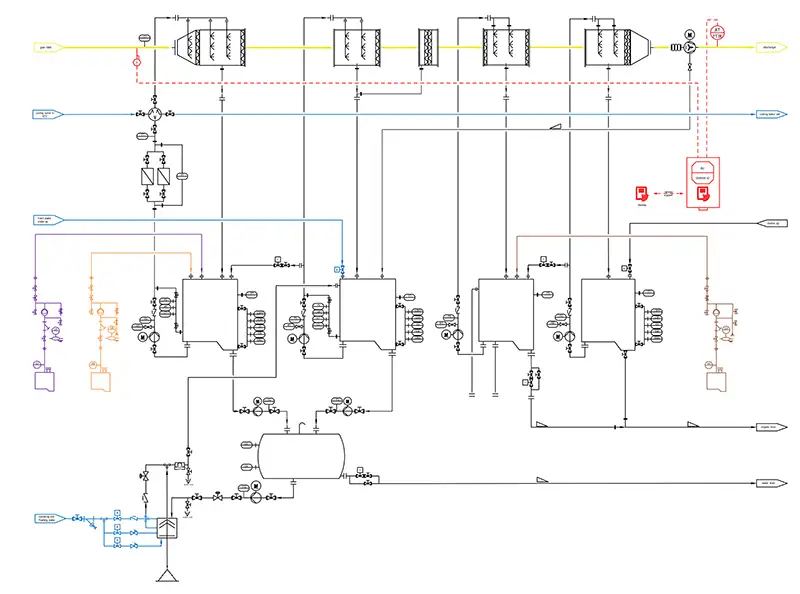

Adaptive wet gas scrubber configurations

When designing and manufacturing the scrubbers, Ravebo considers factors as available footprint, pressure, temperature, corrosion resistance to chemicals to ensure a long service life. For instance, plastic as a construction material offers low weight and good corrosion resistance, low operating costs and a long service life, but on the other hand this is not suitable for high(er) pressures and temperatures. With respect to applications of chemical scrubbers, in most cases a suitable stainless steel will be more beneficial, but in addition of a higher weight, it possesses all the positive characteristics for an exceedingly long service life. The construction of the Ravebo wet gas scrubber installations are adaptive that in the event of future emission adjustments, the scrubber can be expanded or adapted easily without major investment. A completely new scrubber installation is then not necessary.

When designing and manufacturing the scrubbers, Ravebo considers factors as available footprint, pressure, temperature, corrosion resistance to chemicals to ensure a long service life. For instance, plastic as a construction material offers low weight and good corrosion resistance, low operating costs and a long service life, but on the other hand this is not suitable for high(er) pressures and temperatures. With respect to applications of chemical scrubbers, in most cases a suitable stainless steel will be more beneficial, but in addition of a higher weight, it possesses all the positive characteristics for an exceedingly long service life. The construction of the Ravebo wet gas scrubber installations are adaptive that in the event of future emission adjustments, the scrubber can be expanded or adapted easily without major investment. A completely new scrubber installation is then not necessary.

The vertical scrubber

A vertical counter current scrubber offers a very efficient form of (gas) cleaning. The main reason is that there is very intensive contact between scrubbing liquid and polluted gas. This type of scrubber can be fully configured to customer specifications and therefore achieve a remarkably high degree of cleaning.

Principle vertical scrubbers

The polluted gas enters through a side entry at the bottom by means of a half pipe or tangential inflow to obtain a laminar airflow. Counter current spray nozzles then do their job with a fine droplet and optimal spray pattern to capture as many dust particles as possible and absorb aerosols. These spray nozzles can be used with recirculating water. Co-current spray nozzles are also mounted on this same spray line to keep the pre-separator and agglomerator wet for optimum operation and at the same time serve to clean the fin separator.

Advantages of the Vertical Scrubber

- Low pressure drop; by the combination of the pre-separator / agglomerator

- Extremely high efficiency

- Compact construction

- Built to customer specification

The Horizontal Scrubber

This type of crossflow scrubbers consists of a washing chamber with, if necessary, connected reducers to be able to install the whole in a piping system. The horizontal scrubber (or scrubber) is characterized by a simple construction and therefore offers a reliable solution.

Principle horizontal scrubbers

In the washing section, counter current spray nozzles spraying the gas flow are placed with a fine droplet to capture as many dust particles as possible and absorb gas aerosols. The finer the droplets, the better the washer will function. These nozzles have a very homogeneous spray pattern, and these are clogging-free. These nozzles can also be fed with recirculating water. The water must be changed regularly to maintain a good cleaning effect. Water consumption is relatively low.

Removing contaminated substances from the gas stream

Finally, a fine separator is placed in the form of a lamella separator to separate the liquid droplets from the gas stream. The captured dirt particles are then separated in order to be permanently removed from the gas stream.

Advantages of the horizontal scrubber

- Low pressure loss; due to the use of special hollow cone nozzles and the lack of (loose) filling bodies

- High degree of secession.

- Insensitive to pollution; Due to the open construction, dirt particles can hardly deposit anywhere.

- Maintenance-friendly; by simple construction.

- The components can be easily cleaned via an access hatch.