The Role of Green Ammonia in Sustainable Energy Transition

Ravebo’s Open-Spray System for Gas Scrubbing

Customised advise from one of our specialists.

Fill in the form below and we will contact you as soon as possible.

Get in touch with us

The Transition to Green Ammonia

Why Green Ammonia is Crucial for Future Energy Supply

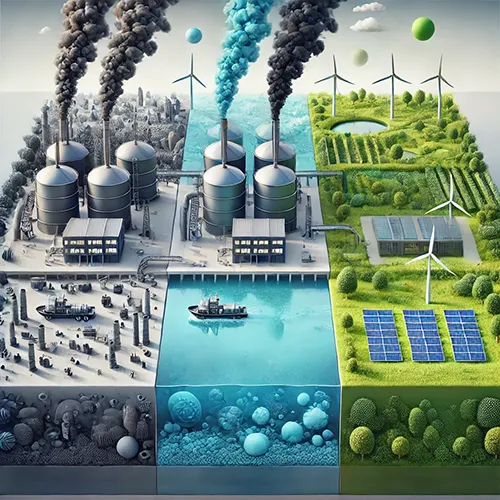

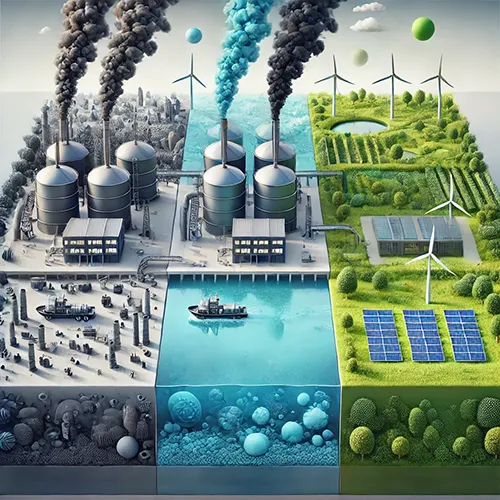

The transition from fossil fuels to renewable and ecofriendly energy sources necessitates that the industry prepares for the large-scale implementation of green ammonia in future energy supply. This requires an expansion of production and storage capacities, the development of additional infrastructure, and careful regulation. Green ammonia offers significant opportunities as an efficient and cost-effective alternative to fossil raw materials and fuels. Consequently, the industry can enhance its sustainability and promote a circular economy.

Green ammonia offers considerable potential as a hydrogen carrier, where ammonia is much easier to store than hydrogen. It serves as an efficient and sustainable fuel to meet the constant demand for fuels and energy. Due to space constraints and the variable output of energy from solar and wind sources, it stands out as an excellent alternative, given the consistent need for energy and fuel.

Dual Purpose of Green Ammonia

Facilitating Green Hydrogen Production and Energy Supply

The utilization of green ammonia serves a dual purpose. Firstly, it acts as a carrier for green hydrogen. It is now widely acknowledged that green hydrogen, alongside electrification, will play a crucial role as a clean fuel. Given the substantial quantities involved, significant production of green hydrogen will be required.

For environmental reasons, the production of hydrogen will often take place in countries where a lot of solar and wind energy is available. By converting hydrogen into ammonia, it can be liquefied, facilitating its transportation globally via tanker vessels. This method allows for the transport and storage of a greater quantity of green hydrogen, owing to the higher energy density of ammonia. Subsequently, ammonia can be stored in large tanks, transported through pipelines, or hydrogen can be extracted using cracking facilities. This green hydrogen can then be utilized as a raw material in industrial processes in an environmentally friendly manner and can also serve as a sustainable fuel.

Get in touch with us

Existing Knowledge in Ammonia Storage and New Challenges

The Need for Expanded Infrastructure and Safety Measures

Significant experience has been acquired in the processing and storage of ammonia, primarily due to its application in the fertilizer industry. However, with the emergence of numerous new applications, there is expected to be a substantial increase in transport and transshipment volumes. This necessitates the development of new loading and unloading facilities, as well as transportation methods such as ships, tank trucks, and railcars, along with the corresponding regulations to ensure safety. Furthermore, green ammonia is a chemical substance that must be handled with utmost caution. This means that the facilities processing this material must be equipped with the highest security measures, and operators working with green ammonia must receive thorough training.

The activities involved in the transportation, loading, unloading, and processing of ammonia are not solely a matter of safety; they also pertain to mitigating environmental impact. Ammonia, at ambient temperature, is a volatile substance that readily escapes during processing, posing risks to both human health and the environment. Consequently, legislation and regulations have been established to govern the handling of ammonia, specifying permissible emission levels. Emission reduction or prevention is primarily achieved through the use of wet gas scrubbers. A scrubber is generally defined as a cleaning system for harmful gases, operating on the principle of absorption facilitated by an appropriate washing liquid, which is typically water mixed with a dosed additive.

The Role of Wet Gas Scrubbers in Emission Reduction

How Scrubbers Absorb Harmful Gases Efficiently

The absorption liquid is circulated using a pump connected to the reservoir where the liquid is stored. The washing liquid is circulated and periodically discharged based on specific water quality parameters. The liquid level is then replenished with fresh make-up water.

Chemicals are typically dosed directly into the washing liquid, which leads to the terminology shift from wash water to absorption liquid. The circulated washing liquid interacts with the contaminants present in the gas, where absorption occurs, and subsequently, both the liquid and the absorbed impurities return to the liquid reservoir. The volume of the liquid reservoir is influenced by the reaction rate or half-life of the impurities within the washing liquid. Generally, it can be asserted that a slower reaction necessitates a larger system volume. The objective is to facilitate the reaction as thoroughly as possible until a stable byproduct is achieved before the washing liquid is reintroduced to the contaminated gas through recirculation via pumps. If the reaction is not sufficiently completed, there is a risk of contaminants being released back into the gas.

Ravebo’s Open-Spray Gas Scrubbing Systems

Efficient Absorption and Lower Energy Costs

The dosing of chemicals should ultimately result in the degradation of harmful pollutants or their transformation into innocuous components that can be easily disposed of and processed. Furthermore, precise dosing with the appropriate chemicals significantly reduces excessive water consumption.

Ravebo utilizes open-spray systems that operate based on the differential velocity potential of liquid droplets through a distribution system featuring spray nozzles and the incoming gas. The droplets are sprayed countercurrent to the gas flow, facilitating contact with the contaminant particles present in the gas. These droplets are generated under pressure, resulting in a uniform spray pattern characterized by a very fine mist and a significantly large reactive surface area, which leads to highly efficient absorption. The scrubbers exhibit lower and more stable pressure losses compared to packed scrubbers and are less complex in design than both tray columns and venturi scrubbers. Furthermore, the open-spray systems function relatively simply, are highly maintenance-friendly, and incur low energy costs.

Game-changing benefits

Discover the game-changing benefits of scrubbers and propel your business forward with our free whitepaper download.

Types of Ammonia: Grey, Blue, and Green

Key Differences in Production and Environmental Impact

Grey, blue, green

What distinguishes grey, blue, and green ammonia? Grey ammonia is produced from natural gas, resulting in the emission of carbon dioxide (CO2). Blue ammonia is generated in a similar manner, with the critical difference being that the released CO2 is captured and either stored or reused. In contrast, green ammonia is produced through the electrolysis of water using renewable energy sources, which results in no CO2 emissions. Both blue and green ammonia are classified as clean ammonia.

Get in touch with our scrubber specialist

Our gas scrubbers with analyzing systems make it possible to clean various gas flows. This leads to a cleaner living environment and more sustainable production processes. Curious about the possibilities? Our specialists are happy to provide you with appropriate advice.