Cutting-Edge Wet Gas Scrubbers and Gas Analyzers for Battery Production and Testing Facilities

Advancing Safety and Sustainability in the Battery Industry with Ravebo's Innovative Solutions

Customised advise from one of our specialists.

Fill in the form below and we will contact you as soon as possible.

Get in touch with us

Advanced Gas Analyzers for Real-Time Emissions Testing

Ensuring Accurate Measurement and Safety in Battery Testing

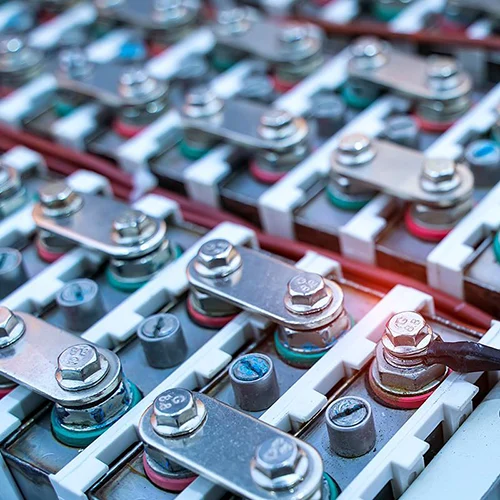

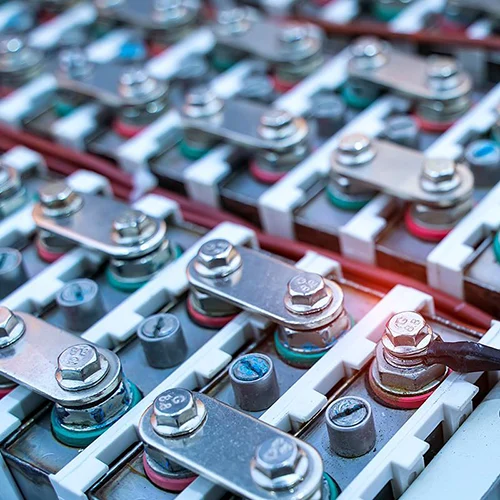

Wet gas scrubbers and gas analyzers for battery production and testing facilities.

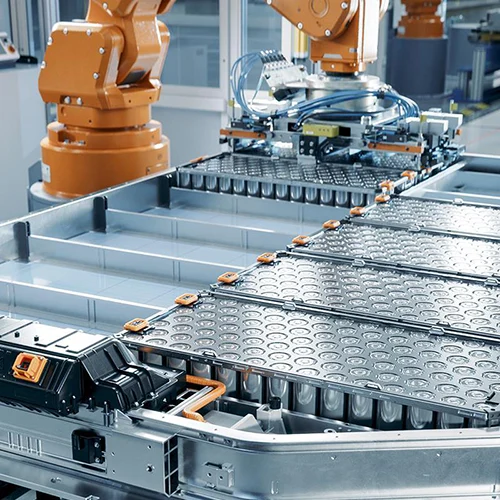

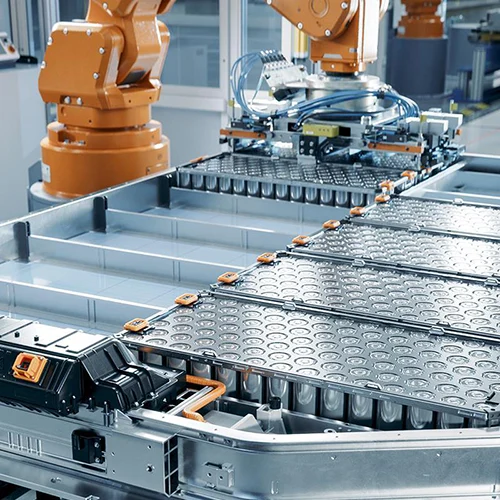

The utilization of batteries has experienced significant growth over the past decade, largely driven by the escalating demands to meet climate objectives. In 2023 for example, the expansion of the battery sector surpassed that of nearly all other clean energy technologies, as decreasing costs, advancing innovations, and supportive industrial policies fueled the increasing demand for batteries.

The costs associated with batteries have decreased by over 90%, marking the most significant reduction among all clean energy technologies. Historically, the predominant types of batteries, particularly lithium-ion, were primarily utilized in consumer electronics. However, the energy sector has now emerged as the largest market, accounting for more than 90% of the total battery demand. In the past year alone, the deployment of batteries within the energy sector surged by over 130% compared to the previous year, contributing an additional 42 gigawatts (GW) to global electricity systems. In the transportation sector, batteries have driven a remarkable increase in electric vehicle sales, rising from 3 million units in 2020 to nearly 14 million last year, with strong growth anticipated in the coming years.

Addressing Risks and Environmental Impact in Battery Production

Enhancing Safety and Sustainability Across the Supply Chain

The utilization of batteries has brought about a significant transformation in the global landscape concerning the extraction of essential raw materials, the manufacturing of batteries, and their subsequent usage and management. This shift implies that various sectors within the supply chain will encounter a range of specific risks. Particularly, the substantial increase in the mining of necessary resources, the activities of manufacturers and factories, as well as the application of batteries, will lead to an escalation in both the risks and the consequences of accidents across all sectors.

It is expected that mining companies and producers will adequately address potential risks through risk assessments and analyses and measures aimed at preventing or significantly reducing the emissions of harmful gases or particulate matter into the environment. However, continuous monitoring is essential due to the significant market pressure that historically often results in increased risk-taking and neglect of environmental concerns. Particularly, consumers, who are frequently unaware, pose a potential risk regarding the safe use and responsible disposal of batteries.

Consequently, it is becoming increasingly important to enhance awareness regarding safety and environmental issues. Governments have anticipated this need for years by establishing standards that producers must consider to ensure that both the production and use of batteries, particularly by consumers, are conducted safely.

Key Standards for Battery Safety and Installation

Understanding EN-IEC 62619:2022, EN-IEC 62485-5, and EN-IEC 62485-1

EN-IEC 62619:2022 outlines the requirements and testing protocols for the safe operation of batteries utilized in industrial contexts, including stationary applications. Examples of applications that involve cells and batteries covered by this standard include:

- Stationary applications: telecommunications, uninterruptible power supplies (UPS), energy storage systems, grid connection, emergency power supplies, and similar uses.

- Mobile applications: forklifts, golf carts, automated guided vehicles (AGVs), rail vehicles, and marine vehicles, excluding road vehicles.

EN-IEC 62485-5 pertains to the installation of one or more stationary secondary batteries with a maximum total direct voltage of 1,500 V. This standard outlines requirements related to safety aspects associated with the installation, usage, inspection, maintenance, and disposal of lithium-ion batteries utilized in stationary applications. The document specifically addresses stationary batteries intended for industrial uses that are installed in separate enclosed buildings or enclosures, as well as those located in public buildings, offices, and private residences. Additionally, this standard encompasses the maintenance and disposal of lithium-ion batteries employed in stationary applications. Key applications include telecommunications, operation of power plants, central emergency lighting and alarm systems, uninterruptible power supplies (UPS), starting stationary engines and photovoltaic systems.

EN-IEC 62485-1 establishes, among other things, the minimum requirements for lead-acid and nickel-cadmium batteries and battery installations concerning safety, reliability, lifespan, mechanical strength, cycle stability, internal resistance, and battery temperature. The requirements may be similarly applied to other battery systems utilizing aqueous electrolytes. This standard addresses safety aspects while considering the hazards associated with: • electricity (installation, charging, discharging, etc.), electrolyte, flammable gas mixtures, storage and transportation.

Battery Testing for Performance, Safety, and Sustainability

Advanced Experimental Methods in Battery Research and Development

The initiative to test batteries focuses on the independent assessment of performance and safety, conducting experimental battery tests for applications in transportation and energy storage. Research is being undertaken to facilitate the integration of batteries into vehicle traction and energy storage systems, thereby contributing to the objectives of low-carbon, safe, and sustainable transportation. Traction batteries are recognized as a critical technology for the drive systems of electric vehicles. This program is designed to address the specific safety risks associated with electric vehicles, ensuring that the safety level for occupants of these vehicles is comparable to that of conventionally powered vehicles.

Currently, there are international testing facilities available that conduct various practical experiments on batteries, including the following:

- Testing batteries in cycles under controlled temperature conditions is a vital evaluation method for assessing performance and degradation. This testing procedure involves the repeated charging and discharging of the battery according to a specific protocol that simulates the expected usage conditions in the intended application. Given the significant impact of temperature on battery performance, it is crucial to maintain regulated thermal conditions.

- The creation of a two-dimensional image (Rontgen) that represents a cross-section of real-time, three-dimensional in-situ imaging of processes occurring within batteries during charging and discharging.

- Mechanical, electrical, and thermal stress tests on batteries, which include high-speed, high-definition video recordings, gas detection/analysis, and thermal imaging. In this context, the battery is intentionally damaged or deformed to accurately map the effects of such conditions.

Ravebo can play a significant role in these tests. Certain tests will result in emissions that need to be measured in real time. The emissions will primarily consist of water vapor, carbon dioxide, various hydrocarbons, and a range of chemicals. This application is particularly well-suited for high-end gas analyzers that have been specifically designed for research purposes.

Game-changing benefits

Discover the game-changing benefits of scrubbers and propel your business forward with our free whitepaper download.

High-Performance Gas Analyzers and Maintenance-Free Wet Gas Scrubbers

Ravebo's Innovative Solutions for Emission Control and Gas Analysis

Ravebo employs the Gasmet GT6000 Mobilis for this application, a portable, mains-powered high-performance multicomponent gas analyzer. The GT6000 Mobilis features a temperature-stabilized sample cell operating at either 50 °C or 180 °C, enabling the analysis of hot and humid gas streams. The system comprises a sampling probe, heated sampling lines, and a pump that may include an oxygen sensor, along with the FTIR analyzer, the GT6000. Both the sampling probe and the pump are equipped with filters that effectively eliminate particles larger than 2 μm with an efficiency of 50%. Calculations based on the spectrum are performed using Calcmet® software, which identifies the concentrations of all components listed in the library. In cases where unknown components are present, the software can facilitate the identification of these components through CLS or peak fitting methods.

It is imperative that the released harmful gases are not emitted into the environment. To address this issue, Ravebo offers wet gas scrubbers that operate based on the open-spray principle. A significant advantage of these systems is their near maintenance-free nature and very low and stable pressure loss, which eliminates the need for large, heavy fans. While many scrubber systems typically require an operator for management, Ravebo believes that, given the nature of the application, scientists should not be burdened with this responsibility. The design of the scrubbers is often vertical, requiring minimal space, and they are delivered fully assembled with instrumentation and control on a convenient plug-and-play skid. Furthermore, the separation efficiencies are exceptionally high, and the scrubbers can be utilized with both polar and non-polar liquids. If necessary, fully explosion-proof versions are also available.

Get in touch with our scrubber specialist

Our gas scrubbers with analyzing systems make it possible to clean various gas flows. This leads to a cleaner living environment and more sustainable production processes. Curious about the possibilities? Our specialists are happy to provide you with appropriate advice.